Considerations To Know About precision machining

The cutting velocity permitted from the slicing Instrument depends on exactly the same factors because the slicing forces and is particularly similar in a fancy way to your Device’s resistance to wear (Figure five).

Machining will get smarter: equipment equipment that Feel? That's the target of the initiative that desires for making a quantum leap in device intelligence

I was definitely excellent at machining and would commit the vast majority of day at the machine reducing and drilling a bunch of various things.

The best Side of machining

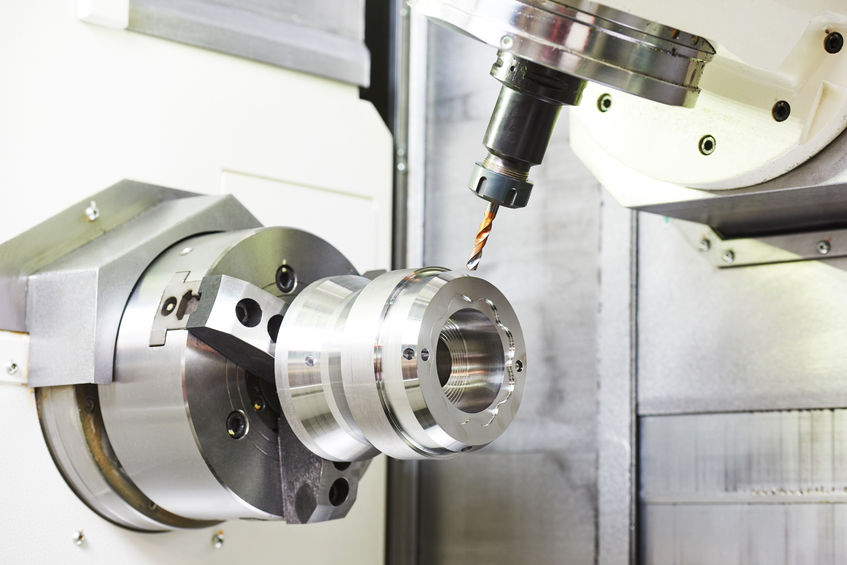

Machining is a part of your manufacture of many metallic items, but it surely will also be made use of on materials including Wooden, plastic, ceramic, and composites.[two] A individual who specializes in machining is named a machinist.

How specific is your measurement? It will depend on the measuring instrument which you use (such as its calibration), how careful that you are, the number of measurements you take, whether you've got permitted for external factors that may affect your measurement.

These voronoi diagrams are employed for making the Resource path for machining. This technique is regarded as being more efficient and robust. In addition, it avoids topological problems connected to common offsetting algorithms.[twelve][13]

In the 1950s, numerical control moved little by little in the laboratory into professional provider. For its to start with decade, it experienced rather constrained impression beyond aerospace operate. But throughout the nineteen sixties and 1970s, NC advanced into CNC, data storage and input media advanced, Pc processing electricity and memory capacity steadily elevated, and NC and CNC machine instruments progressively disseminated from an setting of big businesses and mainly aerospace perform to the level of medium-sized firms and numerous types of items.

CNC Industries, in Fort Wayne, Indiana specializes in precision machining efficiency-essential part pieces principally for Aerospace, Protection and Industrial prospects. Lots of their consumers are big Global providers. Because of their size and really stringent specifications, precision machined sections for this class of consumers may be very demanding.

Considerations To Know About precision machining

With regard to yearly dollars spent, machining is An important with the manufacturing procedures. Machining is often described as the whole process of getting rid of materials from the workpiece in the form of chips. The time period metal cutting is applied when the fabric is metallic.

Find the appropriate content for your personal official source job. See all metals and plastics or filter by a specific home.

Pocket milling has long been considered to be The most extensively used functions in machining. It can be extensively Employed in aerospace and shipyard industries. In pocket milling the material inside of an arbitrarily shut boundary with a flat surface area of a piece piece is taken off to a fixed depth.

Precision machining refers to CNC machining techniques which might be equipped with a computer consisting of a number of microprocessors and storage models.

Indicators on precision machining You Should Know

CNC Industries wholeheartedly agrees that information management is vital to an organization’s achievements. Their facts process has saved them many hours and it has facilitated nearly perfect On-time Shipping and Top quality performance.